Mechatronics Industrial Equipments, Flat no.22, Building no. 3098, Road no. 0469, Block no. 604, Al Qaryah, Sitra Industrial Area, Kingdom of Bahrain

Explosions can cause loss of life and serious injuries as well as significant damage. The aim of the ATEX directive (94/9/EG) is both to apply a single level for health and safety requirements and to overcome trade barriers.

The main purpose of the ATEX directive is to minimize or completely eliminate the risk of ignition in explo- sive areas and to limit the harmful effects in case of an explosion. Explosive atmospheres (Ex areas) can be found where a mixture of air, flammable gases, vapors, mists or dusts are being produced, transformed or stored in the presence of oxygen. This may, for example, be the case in power plants, refineries, chemical facilities, paint facilities, air- and seaport storage tanks.

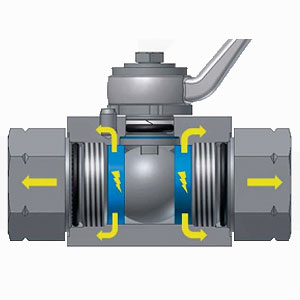

Some supplier declare, that their ball valves hold no potential ignition source in normal usage, and thus do not fall under the scope of the ATEX directive. This is not our approach. All MHA ZENTGRAF ATEX ball valves undergo a conformity evaluation procedure in accordance with the ATEX directive 94/9/EG. During the ignition source analysis, it has been detected that trapped air in the clearance volume between body and ball may cause an explosive atmosphere. By the use of a special sealing material, the diversion of the electric charge can be guaranteed. This applies to all MHA ZENTGRAF ATEX ball valves of the series BKH, MKH, KH, BK3, 3/4 KH, PKH, PK3, MPKH and BEKH.

MHA ZENTGRAF is certified for the ATEX class Ex II 2 Gc

Group II: all industries except underground mining; Category 2: Zone 1 / 21 (an explosive atmosphere is like- ly to occur in normal operation occasionally); Atmosphere G: gas, vapors and mists; Protection Concept c: constructional safety